For many individuals or businesses who are wondering about buying a die cutting machine. They do not know which die cutting machine is best, but choosing a die cutting machine also depends on the machine you are using.

At present, the modernization industry is increasingly improving at many levels in each country. Particular attention should be paid to the textile and printing industry, most of which use die-casting machines to produce more products of the right size and quantity.

All products are made according to many advanced techniques such as quality packaging, design, logo cut business cards with striking colors, or some flyers with slots or tabs. In addition, the die will usually have a pointed tip that acts like a cookie cutter, uniformly shaping plastic, metal, wood, or paper.

If die cutting on a small scale can be done manually with hand-held die-cutting tools or a tabletop electric machine, if it is large-scale and industrial-oriented, it will be done on various types of heavy machine. In particular, die cutting is a flexible and cost-effective printing method. Before choosing a die cutting machine, we should learn a few things like machine type, cost, durability, ease of use, software, flexibility and capacity.

1. Types of die cutting machines

Flat die cutting machine

It is also known as steel rule cutting, is known to be a manufacturing process that uses a flat die cutting press and a custom steel rule die to cut materials into other shapes and designs together. This die-cutting process is suitable for processing thicker materials, large-scale production of larger parts, and means short single completion times.

Moreover, the flat die cutting process will use a flat die cutting press and steel rule stamping die. Often they will be available in mechanical, hydraulic and electrical models with system configurations varying based on the specific installed cutting application.

About a steel rule stamping die includes a custom-designed steel rule, which has cutting elements of the die and die base, including those that hold the steel rule in place and maintain its shape. In addition, there are several types of steel rule molds available including billet die, combination die, progressive die and progressive feed die.

Rotary die cutting machine

It is known for the process of using cylindrical dies attached to a rotary press for flexible material transformation (wed). They are ideal for application in high-precision designs and high-volume production operations.

In addition, the rotary die cutting process will have to use a rotary die press and a cylindrical die designed specifically for it. At the same time, the rotary press uses both flexible and solid cylindrical rotary dies, also depending on the material to be cut, along with the specifications, including the limitation of investment costs and production time. product as originally requested.

Digital die cutting machine

It is also a material conversion fabrication process that does not require the use of a mold. In contrast, they will use lasers, blades, and computer-controlled tools to create cuts, marks, and wrinkles. This type of die cutting has a process suitable for low-cut material conversion applications, but the lead time is fast and therefore low cost still provides high accuracy.

Beside, the digital die cutting process will use computer controls to perform and operate knives, blades and related machine tools. Often the required design information for parts is digitally transmitted to the cutting mechanism to produce the cuts, holes, scores, and creases produced.

Press die cutting machine

This is a device that was previously operated by hand, but later with advanced technology they are operated by machines, they include compact commercial grade presses for many personal use. For industrial grade presses to produce many products in bulk. In nature they will be based on preset dies for cutting, since they are less common, their use is not perfect.

Laser die cutting machine

Known as a modern type of die cutting machine because they use a powerful laser and can move from a sample to the raw material. In addition, it can create many different shapes no matter how complex the shapes. However, with good properties and performance, the cost is relatively high. On the other hand, it is only applicable to large-scale industrial facilities. Since they tend to damage thin materials, consider those that are suitable for laser cutters.

Water jet die cutting machine

For this type, they will use high-pressure water jets that move at twice the speed of other types. This allows them to cut through all types of materials with ease. Since machines do not use heat and they are known to follow the cold cutting process and will not be effective for raw materials.

2. Materials for the die cutting machine

The die cutting process is suitable for a wide range of materials including metal, plastic, paper, fabric, foam, wood and composites. Virtually the converted material and its properties will in part determine the die cutting processes to use for the application, as well as the overall machine configuration and optimal die design.

Flat die cutting machine

The flat die cutting process can convert materials in both sheet and roll form. Most material properties are the thickness and compressive strength of the material as they can affect the design and shape of the die, including the suitability of using the flat die cutting process for the parts. certain die cutting applications. Because they are capable of generating high cutting pressure and are very suitable for cutting through soft and thin materials, as well as hard and thick materials.

Rotary die cutting machine

The rotary die cutting process is capable of transforming web materials. Similar to the flat die cutting process, the way they cut through also affects the rotary die design and the cutting pressure caused by the rotary press. The properties of the material also contribute to the selection of a suitable plastic or solid mold.

Digital die cutting machine

The digital die-cutting process will suit a wide variety of materials including textiles, paper to plastic. However, they are capable of processing low-cut materials similar to flat or rotary die cutting. Very suitable for processing materials with high shear, and for the most part the lead time is much longer.

3. Size and portability of the die cutting machine

The two factors of the size and portability of the die cutting machine are considered as one because these two characteristics complement each other to create the unique characteristics of each type. Based on these two factors, how should you also consider your work area?

Is your material to be cut large or small? What are the properties of each material? And what type of die cutting machine is suitable for the nature of the material and the purpose you use it for? Also, check the weight of the machine if you move it often. Machines can range from 2lbs to large machines of 40lbs.

4. Types of cutting

Cutting is a process of making and using a variety of molds designed, then attached to specialized machinery to convert raw materials. And it is truly suitable for a wide range of materials and applications with different industries. Besides, the die-cutting process still offers several different cutting operation possibilities such as through-cutting, kiss-cutting, punching, scoring, creasing.

Kiss cutting

It is known for adhesive lined material, the cut allows custom design kiss cuts through face layers and adhesive layers, but not through base material cuts. The mold design will not be separated from the parent material but is easily separated from the base layer.

Perforate cutting

It will create holes to hold the die cut design on the fixed surface of the parent materials. And the design will not completely separate from the materials but easily separate along the perforated lines.

Score cutting

It is known to not completely cut the parent material, but rather to leave marks, dents or partial cuts at one point. And the points created are usually only through the cuts in half of the material, which in turn reduces the thicknesses at the stress point, allowing for the formation of square folds.

Crease cutting

It is similar to the grading process, but creases on stock material. One difference of this cut is that the creasing technique shapes the material so that there is an inward bending bulge between the two points so that the stress is parallel. This will increase the flexibility of the material at the folding site and reduce the amount of stress on the material at the fold points.

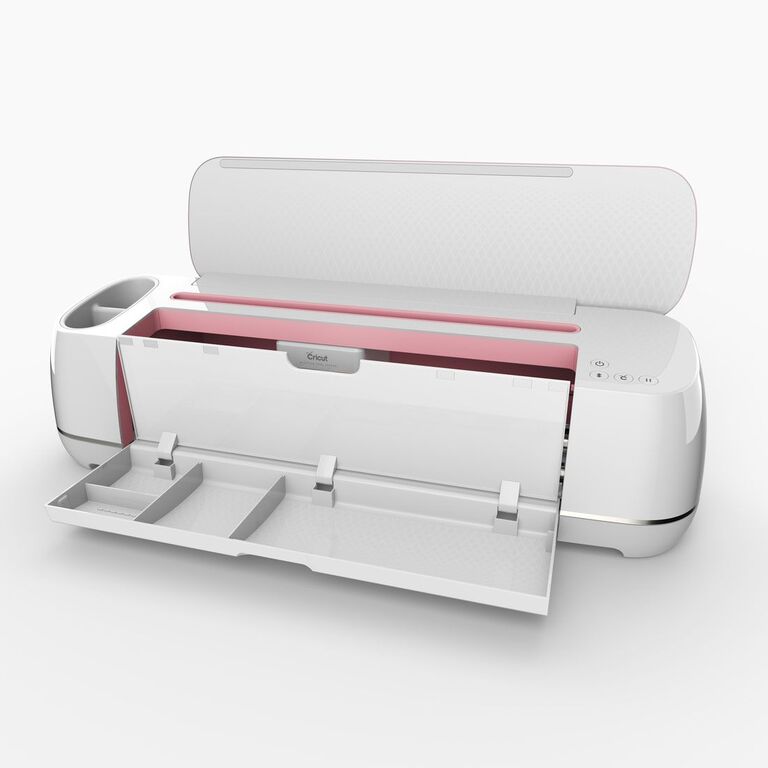

5. Let's have a look on a very cool Cricut product die cutting

With Cricut's original purpose of helping people to work creatively through the use of products we provide tools to make user work schedules convenient in modern life today. And when we came up with the concept of building the first cutting machine, a vision of a simple tool with the potential to completely change the way people think about manufacturing and design.

This helps Cricut continuously innovate the way it looks and create new machines, materials and tools that give meaning and uniqueness to the user. Along with a team of enthusiastic employees in creative work, we believe that we will always update and change to be more suitable for consumers. Here is one of the products that we would like to introduce to you.

The Cricut Maker Machine is a state-of-the-art machine because they can do everything from 3D art to home decor, jewelry, ironwork, vinyl, paper projects. What's more, they can cut over 300 types of materials with high precision, from thin paper and fabric to cardboard and leather. Through their operation, they only rotate using the rotary blade to cut fabric or the blade to cut denser and denser materials to increase the size and depth of the product.

Besides, they are also equipped with some tools to score, engrave, shape and install other decorative effects. Plus, for added sharpness they work with a razor-sharp grading wheel and clear creases.

Conclusion

Through the information above we have outlined a number of benefits to using a die cutting machine, whether you are a beginner in die cutting or are from manual die cutting manufacturers switching to automatic die cutting machines.

Here's the basics of the die-cutting process, the different types of die-cutting dies, and the equipment needed for a die-cutting machine. Note that die cutting machines can have many forms and also depending on the purpose of each individual use, they will work in many different forms.

Usually rotary die cutting and laser die cutting are the two main processes used by most printing companies. In fact, rotary die cutters have to be customized to cut through the substrate. From there the rotary dies can produce various cuts. That is the information we want to send you. Below are some product links you can refer to to choose for yourself a good product. Thanks for reading my reviews.