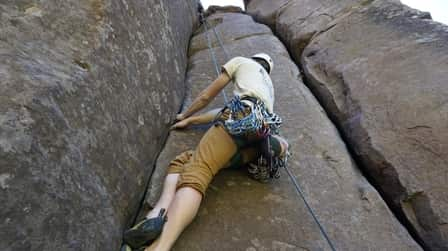

Hundreds of types of climbing ropes, all different brands for you to choose from, but how to find the right one depends on many factors such as thickness and length, or type of ropes, how to choose vines for beginners?

The climbing rope is the rope that ties all the safety chains together and is also the rope that saves your life when you fall. With this set up, it's clear that it's important to choose the best gear for the type of climbing you're doing. There are so many different types of ropes to choose from and so many questions to answer. It is known that each climbing rope goes through rigorous testing and meets certain standards from the forces that the climbing rope transmits and the number of falls.

In addition, the climbing ropes are a legitimate and invaluable means of rescue for many people across the globe, starting with recreational climbers and adrenaline junkies, including lifeguards. However, if you are a first time participant, you should need basic information such as type of climbing rope, climbing pattern, specialized equipment included, structure of each type of rope. . . Based on the necessary information provided, you should first learn the benefits of climbing ropes. As this helps you learn the basics of choosing the right vines for your climbing needs by narrowing it down from the rope beam. Let's find out together.

What are the climbing ropes?

The climbing rope is the rope that ties all the safety chains together and is also the rope that saves your life when you fall. Moreover, the climbing ropes are a legitimate and invaluable means of rescue for many people across the globe, starting with recreational climbers and adrenaline junkies, including lifeguards.

Talking about ropes for climbing, it is divided into two main types of ropes including dynamic and static. The dynamic rope is always designed to stretch to help the climber avoid falling. For stationary ropes with little pull, this rope is very effective for lowering an injured climber, climbing a rope, or pulling on a load. Note, static rope is not used to climb or climb with lead.

Static ropes for climbing

Commonly used in emergencies such as rescues, caving, climbing fixed ropes with associates, and towing loads. With the above concept, the static rope has the ability to not strain the rope if you want to knock down an injured hiker, ride a rope or pull a load with a rope. Do not use static ropes for climbing or climbing with lead.

Half ropes for climbing

The half-rope type is ideal for climbing on high-altitude hike, rock-climbing and ice-climbing routes. Half ropes known as that have to use two ropes. When moving on a cliff, you need to clip one wire to the left guard and the other to the right guard. If done correctly, they will allow the ropes to run parallel and straight, thereby reducing rope resistance on wandering roads. Also, when you tie two ropes together when rappelling goes twice as far with a single string they provide redundancy if a rope gets damaged by falling or being cut by rocks. Besides, it requires you with a lot of skills and a smart mind to control the situation. On top of that, generally the combined mass of the two wires is heavier so the solution here is that you need to transmit the weight while two people use one wire. In addition, we can use half ropes like double ropes to use them and have a 1/2 circled symbol on each end. But still, it is still based on the purpose of use to choose.

Twin ropes for climbing

The twin ropes are suitable for trekking on multi-tier rocky routes, rock climbing and ice climbing. Similar to the structure of a half rope, double rope also consists of two ropes. But with a double rope, you always clip two ropes through each guard. This will have more zippers. On the plus side, they tend to be thinner, making the cord light and less bulky. Plus, two ropes provide redundancy if one rope is damaged by falling or cut by rocks. In addition, double ropes also need a lot of skill and effort for you to climb and cling with two ropes.

On the other hand, the combined mass of two heavy ropes, some twin ropes are also considered half ropes, as they help you use either technique. To identify a double rope by a double rope, there is a circled infinity symbol (∞) at each end.

Single rope for climbing

This type of rope is dedicated to commercial climbing, sport climbing, big wall climbing and top climbing. Single rope is designed to be single wire, and has only one wire, most climbers buy single rope. Besides, single rope also comes in a variety of diameters and lengths, making them suitable for many types of climbing and easier to handle when climbing. However, there are some single ropes rated half or double ropes that allow you to perform any of the three climbing techniques. Usually, single strands are marked with a circle at each end of the string.

How do the climbing ropes make?

In general, today's climbing ropes are made from basic materials such as nylon (also known as polyamide). Most of the nylon fibers used in ropes are made up of superfine fibers. In total, there are 135 superfine fibers in one sheath. The core yarn contains more than 200 fibers. Steps required for the making of the climbing ropes.

Step 1: Twist the yarn

Use core yarn that has been twisted together in pairs. Next, the sheath fibers are also twisted with a core twist, but they have some characteristics; The rafters make the yarn more flexible because they act like a spring, and this will increase the abrasion resistance of the final rope. Then twist the sheath strands 110 to 130 times per meter. While the core fibers are twisted in pairs, in contrast the sheath yarns are twisted in groups of 2, 3, 4 or 5 depending on the characteristics of the end wire. From there these twisted groups form strands that braid together to form a sheath. More twisted cores will create a thick sheath.

Step 2: Steam the rope

After the sheath twist is completed, they must next be removed from the spool and knit loosely. They are then hung on a rack before being put into the autoclave. Since the twisted core yarns are too thick to knit together at this point, most will be wound into loose rolls and hung on the support. Thanks to this process, I believe that the fibers are contracted and easily heated evenly. Besides, the steaming process includes 15 small steps from adjusting temperature, pressure, humidity and sometimes adding chemicals if you want to create color, measuring the exact time interval. It is known that these miniaturization processes are important because they allow the properties of the raw material to be obtained for each rope. This means that the shell and core fibers will also return to ensure they perform the same over time.

Step 3: De-knitting the yarns

Through the step the sheath yarns are shrunk, which must then be de-knitted and fed to the bobbin (or holder), which is used on the braiding machine. Similar process the core fibers are rewound into the spool.

Step 4: Dry core treatment

Through the stage of the cores shrinking, if the treated wire is dry, the core fibers will be processed in a small stage, which is through the machine for water absorption treatment. Depending on the amount of color barcodes produced by the product, you can add a small amount of color dye, so that it is easier to determine if the core is dry treated without affecting the performance.

Step 5: Control the humidity

Given that nylon is susceptible to changes in temperature and humidity, a simple twine in a hot and humid environment will behave and behave differently than twine in a cool, dry environment. Thanks to this, it is possible to ensure the consistency of the fibers at a certain temperature whether used inside or outside.

Step 6: Braid the rope

Regarding the braiding process, there are usually five factors that change the wire handling and strength: Number of carriers (spools) on the machine, yarn tension, braid angle, speed of pulling the rope through the machine, end is the diameter of the hole through which the rope is being pulled. These operations all have a specific consistency: if the braid of the sheath becomes tight and stiff as the braid angles increase, the diameter of the hole decreases as the yarn tension increases.

Step 7: Bobbin on the machine

For braiding, there are two main types of machines that are used to make dynamic wire in the process: 40 bobbins and 48 bobbins. For the 48 bobbin machine produces a finer, flat sheathed rope. Also, give the rope a thick sheath because more strands are braided, which in turn gives better rope strength. And they are more expensive than other types, bulky size leads to slower braiding speed.

Step 8: Dry treatment of the cover

Depending on the type of wire, there will be different drying methods, if it is a Pro dry wire, it has been cored before, followed by dry treatment to cover the outside of the sheath. Because almost the entire rope is put in a bath of waterproofing solution, then dried and cooled. This is also referred to as this "double dry" treatment that coats the shell and core. Importantly, in this process, before processing the ropes, they are stiff but after processing, it becomes smoother and more flexible.

Step 9: Inspect, cut, mark the middle and pack

The rope after production will be about 1000 meters long on the braiding machine. After braiding, if the rope does not dry, it means that it is almost complete and has it checked. Manual testing will measure and ensure there are no tactile or handling deviations across the entire wire. Next, the entire wire passes through the stitch to cut the cord to the corresponding length and mark in the middle. At the end of the middle mark, the staff will check the painted mark and perform the middle mark painting by hand. Then, melt the wire ends and tape the terminals by hand. Finally, pack them. The wire is then rolled up and packed for delivery.

Benefits of climbing ropes

Grip strength of climbing ropes

The implementation of climbing rope techniques, the process of holding the rope (or called the grip) is a very limiting factor if anyone is just starting to participate. If your back is strong, but you don't have a great grip, then deadlifts will be limited. Climbing rope is known as a way to build grip strength. When climbing, you should hold your own weight for an extended period of time. Next, you must fight gravity with each hand as you attempt to climb, which forces the handle to work unilaterally and stabilizes the body.

Arm strength of climbing rope

In the process of climbing rope, except for the legs that help push the body weight up, arm strength is also quite important because the arms are forced to extend and then pull your whole body up. This creates another force for the arms such as chin-ups or pull-ups. Thanks to the pull up, your arms can take longer and pull forward stronger. When pulling, force one and both arms to work simultaneously.

Back strength of climbing rope

Rope climbing can greatly strengthen your back muscles and upper back muscles. During the climb, you must pull yourself close to the rope, and the direction of this motion forces the slings to work when pulled up or raised.

Improve your health and spirit

If you participate in rope climbing in many different forms or consider it a sport you love. In addition to bringing obvious benefits in strengthening the body's muscles, climbing rope stimulates and strengthens your mind a lot.

Muscular endurance

Except for gym sports to improve your muscles. Rope climbing is also an option that can greatly enhance your physique. Because it allows you to develop endurance and even the ability to control your body's weight.

Conclusion

What you need to look for in order to select climbing vines are shared by us above. However, regardless of what you want them to be, where you want them to function. Overall, there are many different types of strings and brands to choose from, which we'd like to remind you of is based on the feel of what you like about that string. For example you can buy a single 60m rope with a diameter of 10. 0mm and a weight of about 62g per meter. Thank you for reviewing our news.